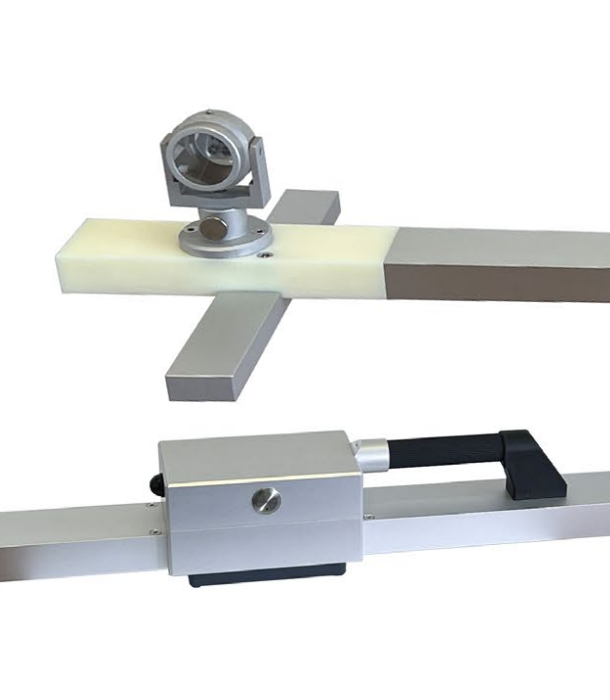

Trimble GEDO Track Measuring Bar

For slab-track construction or direct-fix installations, the Trimble GEDO Track Measuring Bar follows the same trusted Trimble GEDO Track workflow as the Trimble TMD.

Thanks to its portable design, it offers greater flexibility and productivity on busy construction sites, making it an ideal solution for dynamic work environments.