Monitoring Solutions

We have a range of monitoring solutions and services

Overview

UPG offers one of the most complete monitoring portfolios available, with a solution for nearly any monitoring project. We are experts in system automation and nearly any sensor can be automated, whether new or existing.

We specialise in offering full turnkey solutions, including items such as instrument shelters, remote communications and solar power systems, so implementing a monitoring project has never been easier.

Whether you want to monitor a mine, tailings dam, rail or structure, we have a solution for you, and offer a full service, including consultation, system design, equipment supply, implementation, and commissioning, along with lifetime support of your system.

We use the latest technologies which ensure our solutions are on the cutting edge and all operate within a single software ecosystem, regardless of the field hardware.

So, no matter how big or small your project is, we have a solution for you.

Our prism monitoring systems use the latest technology from Trimble, to provide one of, if not the most robust and reliable total station-based slope monitoring solutions on the market.

The Trimble S9 monitoring instrument has a reputation for accuracy and longevity, even in the harshest of environments. The same instrument can be used for either manual monitoring projects, or fully automated real-time systems and represent market-leading value for money.

Real-Time Automated Systems

For projects requiring high measurement frequency, our Real-Time Automated Systems provide 24/7/365 unsupervised measurements and data processing, with unprecedented levels of reliability.

The system will automatically measure prisms, download and process data, execute analysis, issue notifications, and raise alarms. All within seconds of each round measurement!

The industry-leading levels of reliability of our automated systems are achieved with the utilisation of the M1 Monitoring Controller, in conjunction with the Trimble S9 Instrument.

The M1 controller is a combination of field controller, device server, and computer. It simplifies field installation and has fewer hardware components than traditional systems.

It is co-located at the instrument pillar and performs both the measurement and storage duties at a local level for each round measurement, as well as the automatic file-based transfer of measurements, to the monitoring software.

Therein lies the advantage of never losing round measurements to communications dropouts. The TS and M1 controller will continue to operate as normal, even if there is a communications outage. When communications are restored, all stored round information is automatically backfilled and processed by the software.

UPG makes the implementation of automated monitoring systems very easy, with the provision of accessories and services which result in turnkey solutions. These include support and consulting, design of bespoke communications systems, design of customised solar power systems, fully engineered cyclone-resistant instrument shelters, and full on-site commissioning of these systems.

In addition, the Trimble 4D Control monitoring software can be used to process and analyse more than just Automated Total Station measurements. Combine data from GNSS measurements, your manual monitoring projects, Automated Geotechnical sensors, Engineering sensors, and Weather Stations and more, to create a comprehensive multi-faceted monitoring solution, all offering fully automated workflows.

Manual Monitoring Projects

Manual monitoring projects use the Trimble S9 instrument, coupled with a dedicated field controller app, Trimble Access Monitoring, which is part of the Trimble Access field controller software ecosystem.

The Monitoring App is compatible with the entire range of Trimble Field Controllers. The app will effortlessly take care of the round measurement, with just a simple instrument orientation required from you.

Downstream of the field measurements, exports from the field controller allow full scalability for data analysis. This ranges from free software options, such as spreadsheets and Trimble 4D Lite, third-party applications, or Trimble 4D Control Monitoring software, for users requiring full functionality solutions that include semi-automated processing workflows, data analysis, and alarming functionality.

With the recent failures of tailings facilities around the world, there is a growing interest in monitoring solutions that enable early detection of situations that could lead to such failures. Our monitoring solutions encompass a wide range of the latest technologies, to offer comprehensive monitoring using a multi-faceted approach.

Total Station Based Prism Monitoring

Total station-based prism monitoring, offers one of the most accurate and complete solutions, yielding unrivalled short and long-term 3D positioning performance. This makes them ideal for identifying where displacements and/or settlements occur on structures such as embankments as well as for tracking movement trends over time.

They can be applied to simple low risk and infrequent manual monitoring tasks, or as fully automated systems as required for high risk situations or high frequency measurement cycles. They can be used as a standalone solution, or in conjunction with other sensor types, all within the same monitoring software environment.

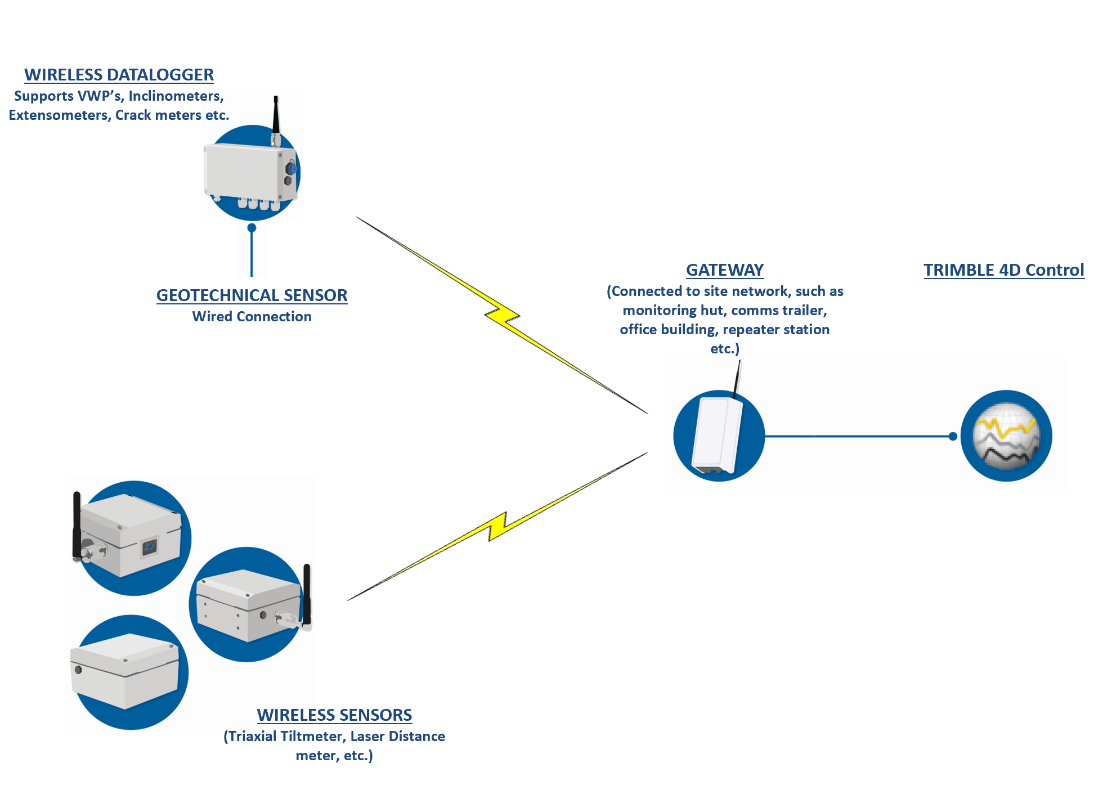

Wireless Sensors and Nodes

Commonly used in conjunction with Total Station systems, or as a standalone solution, our extensive range of wireless sensors and nodes support nearly every kind of geotechnical or structural sensor and application. These include, but are not limited to; Vibrating Wire Piezometers, Crack Meters, Extensometers, Inclinometers, Water level Sensors, Tiltmeters and many more.

The wireless nodes facilitate the connection of all local wired sensors and are fast and economical to set up. This ensures that you can easily set up a wireless node at each sensor array/hole location, eliminating the need for long cable runs to telemetry stations. This greatly reduces the risk of cable damage. These wireless IOT devices have fully integrated power and long-range communications, eliminating a raft of field hardware required by older technology. They do not need any solar power or external radio systems. This makes for a very easy installation and nodes are easily portable to other locations.

All wireless sensors and nodes are connected to a single gateway device, with a communications range of up to 15km. This gateway is accessible through the local site networks only or can be fitted with a SIM card to allow 4G connections where there is no network infrastructure. The gateway serves as the collection point for the data from all the field sensors and has a direct network connection to the monitoring software. This provides a seamless and fully automated data transfer workflow, with no additional field components or software required.

All data storage, visualisation, analysis and alarming, is provided by the same Trimble 4D Control software used by all of our monitoring solutions, and offers the ability for a multi-disciplinary approach, incorporating multiple sensor types. Alternatively, they can be used as a standalone system, providing the raw data only. Fast, simple, and effective!!

These wireless devices can easily be retrofitted to your existing sensors on-site, offering you the chance to automate your existing manually read sensors.

Digital Weather Sensors

Monitoring Rainfall on-site forms a critical part of a tailings facility monitoring project. We provide digital weather sensors as part of our solutions. These are installed directly at your facility, providing data as local as it gets. Often, you need to rely on rainfall data provided by the next closest sensor, which could at times be located a long way away from your facility.

The ability to have up-to-date, real-time rainfall and other weather data, based right at your facility location, provides valuable information that can be used in conjunction with analysis of data from other sensors. Whether you are after short-term rainfall intensity data or long-term statistical analysis, our systems record it all. As with all our solutions, this is a fully automated process, with seamless data transfer to the monitoring software.

Laser Scanning

Laser Scanning is a relative newcomer to tailings dam monitoring solutions. Inhibitors to widescale usage of this technology include; high capital cost of equipment, convoluted and time-consuming data processing, specialized skillsets, and the inability to find a balance between scan accuracy, repeatability, resolution, and speed. Enter the revolutionary Trimble SX12!!

The SX12 combines all the accuracy and workflows of a Total Station (and the price to match!!), with the speed and resolution ideal for scan-based monitoring and change detection. Scan areas can be easily and accurately repeated for periodic monitoring purposes and resultant data can be used for scan-to-scan or scan-to-surface comparisons. You can then generate user-definable heat maps to visualize any changes that have occurred. If that isn’t enough, the SX12 can also be used as a manual monitoring total station, measuring to prisms for manual prism-based monitoring projects. This allows the use of a single instrument to provide vastly different types of information. Power and versatility in one package!!

Our extensive range of wireless sensors and nodes support nearly every kind of geotechnical or structural sensor and application. These include, but are not limited to; Vibrating Wire Piezometers, Crack Meters, Extensometers, Inclinometers, Water level Sensors, Tiltmeters and many more.

They are suitable for a wide range of projects, are easy to deploy and offer a cost effective and diverse solution for wireless automated systems. Manual data collection is a thing of the past. Now, the data comes to you.

Used as a standalone solution, or as part of a multi-disciplinary approach, they can offer the most basic data delivery or full integration into the Trimble 4D Control software.

Trimble 4D Control software has a standalone Geotechnical Edition, which supports all the below sensors and nodes. Easily scale this up to accommodate more complex projects requiring additional sensor types, such as Total Stations or GNSS.

Below is a summary of some of the wireless devices used in our systems:

THE VIBRATING WIRE (VW) LOGGER

The vibrating wire (VW) one-and-five channel data loggers easily connect vibrating wire instruments such as piezometers, load cells, strain gauges and pressure calls to the monitoring software. The vibrating wire data loggers are autonomous battery-powered devices with C-size batteries that can last up to 10 years with minimal to zero maintenance required. The units may also be used as standalone loggers for manual monitoring and can be easily configured and connected with a USB cable and an Android phone.

THE DIGITAL LOGGER

The Digital logger brings the advantages of electronics to the geotechnical world. It can easily connect a wireless network with in-place inclinometers (IPIs) on a chain in a hole or excavation, multipoint borehole extensometers (MPBX) and other sensors from leading manufacturers. It transforms manual and sporadic data collection to a more regular and automatic process, making it the most cost-efficient way to capture data from any environment.

THE ANALOG DATA LOGGER

The Analog data logger admits most inputs from analog sensors, such as voltage, 4-20mA, potentiometer, FWB, thermistor or PT100, allowing it to easily connect load cells, strain gauges and pressure cells to your monitoring system.

THE LASERTILT90 WIRELESS SENSOR

The LaserTilt90 wireless sensor is a 2-in-1 laser distance meter and tri-axial tiltmeter. The laser measures the relative distance between pairs of reference points. One of the two points can be a natural surface or target foils while the node can be placed at the other endpoint. Meanwhile, the tiltmeter provides measurements of changes from the vertical level, either on the ground or in structures, and is used to monitor inclinations, movements, and differential settlements of slopes or infrastructures.

Individual laser sensors and tiltmeters are also available where a combined sensor is not required. The laser sensor is ideal to deploy in situations such as tunnels and overpasses, where convergence/divergence monitoring is required. It can also double up as an optical crack meter, to easily monitor joints or other structures.

So, how do these all work? Simple really. The basic diagram below describes the workflow used in getting data from the field, to the office. The process is very simple, with minimal field hardware and setup required. All processing and data analysis is performed automatically by the monitoring software following automatic data transfer.

The above sensors and nodes equip you with everything you need for virtually any geotechnical or structural engineering monitoring project, and we can help you with the design and implementation of your project, whether it be a rock on a hill, a tailings dam, mining pit, overpass, railway line or bridge.

We have a range of sensor options that provide scalability and flexibility for your rail monitoring project. These include manual or automated Total Station based measurements, or our range of wireless sensors and nodes, with industry leading range capability. Or, you can combine any number of sensor types for a multi-disciplinary approach.

Our Total Station based systems offer fully autonomous operation, 24 hours a day. They offer accurate 3D positioning, monitoring both horizontal and vertical track displacements, while the Trimble 4D Control monitoring software allows for a raft of further mathematical variables derived from this base information, to form part of simple or complex automatic analysis and alarming.

Our wireless sensor range most commonly used for rail monitoring includes; tri-axial tiltmeters, optical displacement sensor or a hybrid sensor that is a combination of both.

Tiltmeters offer the ability to accurately measure rail cant, longitudinal displacements, as well as settlement. These sensors can be daisy-chained together in the software, to offer multi-sensor longitudinal analysis potential, rather than looking at an individual sensor in isolation. These sensors can also be used to monitor structures within the rail corridor, such as bridges, buildings etc.

Our wireless optical sensor can be deployed to easily monitor track slew at desired locations, or to monitor other related structures, such as convergence/divergence in tunnels and bridges or embankment stability.

If you need comprehensive deliverables from a single sensor, you can choose our hybrid sensor that offers all the functionality of both the tiltmeter and the optical sensor, all in one.

All of this is underpinned by fully autonomous operation and seamless and direct data flow into the monitoring software, which acts as your sentinel and notifies you of any displacements outside of tolerances.

Don’t know where to start? Talk to our experts who can consult and advise you on everything you need for your project, as well as assist with the implementation and ongoing technical support.

One of the most commonly mentioned roadblocks to implementing a monitoring project is the intimidation factor!! Monitoring projects, especially complex multi-disciplinary ones, ultimately require a host of specialist technical knowledge to successfully implement.

UPG is well placed to eliminate this intimidation factor, as we offer a range of services that result in turnkey solutions. Instead of being a mountain to climb, we can make your monitoring project completely effortless, with our all-encompassing solutions all under one roof.

Equipment Supply

We supply a wide range of equipment and accessories to fully meet your needs for nearly any kind of monitoring project. This includes GNSS receivers, Total Stations, Digital Weather Stations, Wireless Sensors and Nodes, as well as the associated Monitoring Software. In addition to this, we manufacture complimentary systems such as customised enclosures, instrument shelters, communications systems, and solar power systems, to offer everything needed for even the most complex monitoring project.

Consultation

We recognise that not everybody is an expert in all fields of technology. This is why we offer a free consultation service to give our expert advice on how to effectively go about implementing your project. From designing customized point-to-point communication networks, or equipment-specific solar power systems, to advice on sensor arrays and appropriate methodologies. We draw on many years’ worth of experience, combined with on-site reconnaissance, to ensure we get it right the first time. This culminates in the use of appropriate and well-integrated technologies, with reliable long-term performance.

System Integration and Commissioning

There are few monitoring projects that allow the use of off-the-shelf systems. Typically, a complex monitoring project would require the use of a number of different technologies, covering hardware from different suppliers, communications and power, software integration, and the ability to conform to stringent IT policy. Trying to combine all of this into a comprehensive and turnkey solution requires multi-disciplinary expertise and experience.

UPG has all the experience gained from a proven track record of implementing many complex monitoring projects over the years, along with a fully equipped workshop and support infrastructure, to offer a full in-house integration service.

But, it doesn’t end with equipment arriving on-site on a pallet. Our service extends to full on-site system commissioning, giving you the confidence that you have a complete and fully operational live monitoring system before we leave the site.

Support and Training

Sometimes, things go wrong!! Although they are extremely robust and reliable, our monitoring systems operate off the back of site infrastructure and conditions that neither you nor we have full control over. So, when you experience technical difficulties and run out of ideas, you need someone to turn to. UPG draws on years’ worth of relevant industry experience to help you out with virtually any technical difficulty you may encounter. In addition, UPG has access to the might of a global network of Trimble product specialists, so we can get to the bottom of any technical hitch, no matter how complex.

At UPG, we are confident that the solutions we supply are of the highest quality, and are robust and long-lasting. In fact, we back this up with a promise of free, world-class technical support for your system…for life!! There are no expensive support contracts attached to our systems. Your investment in our systems is enough to guarantee you will have a helping hand when you need it.

In addition, we offer full software training, both office-based, or on-site, to ensure you get the most out of your system.

Automation

Not all monitoring projects are new projects, enjoying all the benefits and conveniences that modern technology provides.

There is a sea of existing projects out there, reliant on outdated technology and workflows, most of them requiring manual data collection, processing and analysis, and reporting. This is very time-consuming and is a further drain on already pressurised human resources. But, all is not lost!!

The cutting-edge technology UPG uses can easily be retrospectively integrated into just about any existing manual system. We can turn time-consuming workflows into fully automated ones, from just addressing automatic data reading and transfer aspects, to fully aggregating and integrating multiple sensor types into a single software ecosystem.

Successfully implementing a monitoring project usually requires the integration of a number of fringe technologies, devices and equipment. All the better if your supplier has all these in-house!!

UPG provides all of these ancillary products and solutions, as part of the systems that we supply and commission. This is the key to our ability to provide a turnkey solution for your monitoring project.

Our monitoring accessories include items such as monitoring prisms and adapters, pillar plates and Instrument brackets, backsight prism systems, enclosures, antennas, and cabling.

Then, in addition to the 1st tier monitoring equipment such as Total Stations, GNSS Receivers, Wireless Sensors and Nodes and Software, we also provide the below range of supporting products.

Instrument Shelters

Although all our equipment is fully IP rated, providing some shelter to your equipment will give additional weather tolerance and protection from other sources of damage. We provide two instrument shed options; a lighter duty shed for general use, as well as a heavy duty shed for use in cyclone affected regions. The heavy duty shed is fully engineered and certified for use in Region D wind zones. These are regions subject to the most severe Cyclonic conditions.

Solar Power Systems

If your monitoring project lies outside of an urban area, chances are you are going to need to provide an independent source of power for your monitoring equipment, such as total stations etc. Our solar power systems are custom designed for each project, region and device, ensuring you have the right amount of power at your disposal, even when you experience long periods of cloudy weather.

They are designed with appropriate reserve levels which prevent damaging your batteries due to over discharging them. Our offerings include both a pole mounted system, for installation convenience, as well as a ground mount option, which is suitable for use in cyclonic wind region D.

Communication Systems

Our monitoring systems can easily make use of existing site communications, such as wireless meshes and private LTE networks, or even public 4G mobile services. However, when these are not available, it may be necessary to use a dedicated custom communications system to connect your field devices to the office. Our team is very experienced in designing and supplying robust long-range communications systems, offering extended reach for your monitoring project, even if it is very remote. Our solutions include all the devices required on each end of the communications chain, as well as fully self-contained, self-powered repeater systems, offering even further communications range potential. All our systems are fully configured and integrated into site networks during the commissioning phase.

Field solutions aside, your choice of monitoring software greatly influences the deliverables you achieve with your entire monitoring solution. 4D Control is Trimble’s premium monitoring software solution, offering you the ability to scale your monitoring software according to your project needs. Whether you just want to run a few geotechnical sensors, a manual total station, or automated systems, Trimble 4D Control does it all.

The combination of automated field measurement and processing routines, data transfer, data display and analysis, as well as powerful alarming capabilities, make Trimble 4D Control one of the most complete monitoring software packages available. This is why it is widely used by some of the biggest mining companies in the world!!

Trimble 4D Control forms part of a wider solution ecosystem, comprising both Trimble monitoring hardware and software and yielding the power and reliability that seamless continuity between the office and the field provides.

Full user access control ensures that everybody has the appropriate levels of access, ensuring nobody has unauthorized access to your data.

Field Software

Manual monitoring projects use the Trimble S9 instrument, coupled with a dedicated field controller app, Trimble Access Monitoring, which is part of the Trimble Access field controller software ecosystem.

Just point your total station in the right direction and the monitoring app measures your round from there. Copy the file to your hard drive and the 4D Control software automatically processes and analyses your data.

Nothing could be easier!